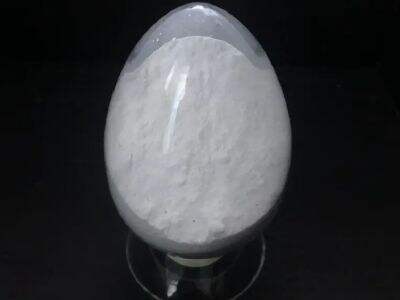

High temperature resistant materials such as MgO are important requirements when industrial furnaces must be refractory to extreme temperatures. It is crucial that these materials are of high enough quality to ensure the furnaces are operating efficiently and that they are as long-lasting as possible. Now, let’s delve deeper and find out why the high temperature resistant MgO is critical to industrial refractories.

To maintain longevity in high heat situation:

Industrial furnaces are used in applications where a large, high temperature furnace is required to melt materials such as hardware, glass or ceramics. This extremely high temperature causes great hardship for the substances that the company used to make the furnace. Without proper high temperature resistant materials, the flames and heat from the furnace can cause the pipe and other components to rot away, and you’ll end up needing a costly repair or replacement.

However, as mentioned earlier, reasonable use of industrial furnaces:

With its superb high heat resistance and thermal shock resistance, high heatproof MgO is widely used in the industry for its high temperature properties. This is why industrial furnaces are lined with MgO refractories – they resist changes in temperature without cracking apart. Industrial furnaces can achieve a longer service life and more effective performance with MgO, which can also save companies time and money.

All-rounder – High-temperature resistant for good working processes:

Time is, after all, a factor in industrial environments. Proper and efficient operation of production processes is essential. MgO resistant to high tempaturehigh temperature resistant Product Product MärkteMgO helps industrial furnaces to work under working temperature without breakdown product quotes It means that the furnaces with MgO has a steady temperature at industrial working, → and removes product stops. This guarantees error-free and rapid product production, resulting in more efficient operation of the production facility as a whole.

Industrial application Preventing premature failure of refractory linings:

Industrial furnaces are protected on the inside from harsh conditions by refractory linings. Without properly heat resistant materials, they can fail early and cause downtime and loss of production. MgO refractories are particularly made to be resistant to high temperatures as well as extreme chemicals so that the lifetime of refractory linings is long.

Key role played by high temperature resistant MgO for the determination of production consistency:

In the industrial manufacturing world, consistency is crucial. Variation caused by management or movement of the mould, differences in heat transfer between the tire layers, and especially feedstock integrity can have significant consequences including scrap product or complete process stoppages. A high temperature resistant mgo in food allows for uniform insulation which leads to an even stable temperature inside of industrial furnaces to produce high quality products each time. With the help of MgO refractories, companies have a good tool to keep their production running and performing as it should, which should keep their bottom line positive and customers happy.

Table of Contents

- To maintain longevity in high heat situation:

- However, as mentioned earlier, reasonable use of industrial furnaces:

- All-rounder – High-temperature resistant for good working processes:

- Industrial application Preventing premature failure of refractory linings:

- Key role played by high temperature resistant MgO for the determination of production consistency: