You know what abrasive tools are right? These tools are unique to people in working with them into fixing or cutting hard materials. These tools are commonly found in construction sites to build or repair buildings and roads. A very useful tool, because it can remove things like paint, polish (metal and ceramic too) In good construction work, abrasive tools are used to remove unwanted material on specific surfaces to achieve smooth and clean results.

Ever wonder how abrasive tools get their bite? The secret simply happens to be a material called magnesium oxide. Safety - magnesite is used as a bonding agent for abrasive compounds. This material makes the tools easier to fine grinding and cut off hard things. Due to magnesium oxide, the labor can begin tougher jobs by implying abrasive tools.

Main ingredient of abrasive tools: magnesia Magnesium oxide is a special material and plays an important role in the production of high-quality grinding wheels. It holds so much magic within it. The first one is hard - which means it does not break easily under a lot of pressure. Secondly, it is powerful and sturdy activewear that will withstand everyday wear. It is also very heat resistant which makes it a great tool when you are working in areas of high temperature. These traits make magnesium oxide an excellent option for producing durable and reliable abrasion tools that people can depend on.

Magnesium oxide is one of the hardest material in known. The resulting hardness enables these abrasive tools to slice through unforgiving materials like metal or stone with little resistance, and allows for more efficient work from the part of laborers.

Resistant To Heat: Magnesium oxide has a heat tolerance which means it does not change when heated at high temperatures. This means that it does not warp or degrade as in the case of tools made from other materials, and is crucial for hot working or fluctuating environments.

Cheap: Compared to other materials, magnesium oxide is a lot cheaper when used for making abrasives. The downside is abrasive tools become less expensive for all, be it the construction giants or small scales businesses.

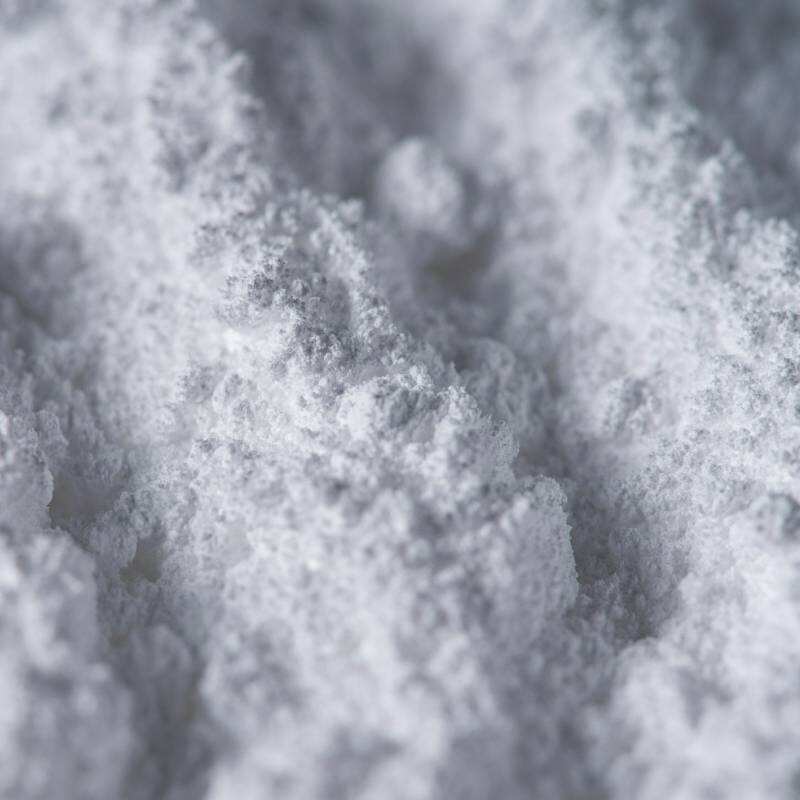

White solid used in the abrasive manufacturing process is magnesium oxide. In different domains it is used to solve the number of problem Statement. For abrasive tools, it makes the instruments durable against high-temperature hardness and strong. Due to its performance enhancement characteristics, magnesium oxide is an important role in the development of abrasive tools.

Dafei's R and D team magnesium oxide for Abrasive tools of highly sophisticated professionals. there numerous sub factories. Daffie a manufacturer numerous product has several patents. magnesium hydroxide slurry invented produced Daffie has been certified many authoritative organizations.

Dafei certified SGS well other organizations. They many magnesium oxide for Abrasive tools high-quality the magnesium hydroxide solution. Dafei global business more 200 clients. provides vast selection top-quality services products earned high praise industry experts.

regular products: ordinary magnesium oxide for Abrasive tools hydroxide; high-purity hydroxide; high-quality, modified magnesia hydroxide; regular magnesium oxide well as high-purity magnesite oxide.

Dafei magnesium oxide for Abrasive tools partnership several excellent logistics firms provide customers around globe secure reliable logistics services make sure goods get destination safely.

Copyright © Dafei(Shandong) New Material Technology Co.,Ltd. All Rights Reserved - Privacy Policy - Blog